Introduction: Luncheon meat, a popular snack worldwide, is often utilized in sandwiches and recipes. This article takes a deep dive into the intricacies of luncheon meat, covering its types, production process, preservation methods, and health concerns.

Table of Contents

What is Luncheon Meat?

An exploration of the definition and origin of luncheon meat.

- Origin and Definition:

Luncheon meat, commonly referred to as luncheon, is a processed meat product created by mixing together meat or chicken along with various spices and fats. The meat used may vary, but it is typically pork or sometimes poultry like chicken. The mixture is then formed into a loaf shape and canned for preservation. Luncheon meat is a versatile food item that can be sliced, fried, or eaten cold straight from the can. Its convenient packaging and long shelf life make it a popular choice for quick meals or on-the-go snacks.

The term “lunchtime” in luncheon meat’s name is derived from its historical usage as a common component in lunchtime meals. Luncheon meat gained popularity during the mid-20th century as a convenient and affordable option for sandwiches and salads. It became a staple in many households due to its convenience and versatility. Luncheon meat can be used in various recipes, such as sandwiches, salads, casseroles, and appetizers. Its savory flavor and ease of preparation make it a go-to ingredient for quick and simple dishes.

Although luncheon meat is a convenient and tasty option for meals, it is important to consume it in moderation due to its high sodium and fat content. Some varieties of luncheon meat can also contain preservatives and additives, so it is advisable to read the labels carefully before purchase. Despite its processed nature, luncheon meat remains a popular choice for many people looking for a quick and easy meal solution. Whether enjoyed on its own or incorporated into recipes, luncheon meat continues to hold a place in the culinary world as a convenient and versatile food item.

- Key Takeaway:

Luncheon meat is a type of processed meat product that is typically made from a combination of ground pork, beef, or chicken. The meat is finely mashed or pureed into a smooth consistency, mixed with various seasonings, and then formed into a loaf or can-shaped product. It is often precooked during the manufacturing process, making it ready to eat or easy to heat up for a quick meal or snack.

One of the most popular brands of luncheon meat is Spam, which is a canned meat product introduced by the Hormel Foods Corporation in 1937. Spam is renowned for its long shelf life, making it a convenient pantry staple for many households. Luncheon meat can be enjoyed in a variety of ways, such as sliced and pan-fried, added to sandwiches, diced and tossed into salads, or even eaten cold directly from the can. Its versatility and long-lasting nature have made luncheon meat a popular choice for campers, hikers, and those in need of non-perishable food options.

Despite its convenience and popularity, luncheon meat has been subject to some controversy due to its high sodium and preservative content. Excessive consumption of processed meats, including luncheon meat, has been linked to health issues such as high blood pressure, heart disease, and certain types of cancer. As a result, many health experts recommend consuming luncheon meat in moderation and opting for leaner protein sources whenever possible. While luncheon meat can be a tasty and convenient option for meals and snacks, it is important to be mindful of portion sizes and overall dietary balance for optimal health.

How is Luncheon Made?

A detailed overview of the production process of luncheon meat.

- Production Steps:

The process of making luncheon meat is a detailed and meticulous one. It starts with deboning the meat, which typically comes from pork, chicken, or beef. This step is essential to remove any bones that may affect the texture and quality of the final product. Once the meat is deboned, it is then ground into a paste-like consistency. Grinding the meat helps in creating a smoother and more uniform texture in the luncheon meat.

After the meat has been ground, it is time for seasoning. This is a crucial step as it determines the flavor profile of the luncheon meat. Seasonings can vary widely depending on the desired taste, but common ones include salt, pepper, garlic, and various herbs and spices. In addition to seasonings, additives like binders and fillers may also be mixed in at this stage to improve the texture and extend the shelf life of the luncheon meat. These additives can help maintain the shape of the meat during cooking and canning processes.

Once the meat has been seasoned and mixed with additives, it is then cooked. Cooking ensures that the meat is safe to eat by killing any harmful bacteria present. After cooking, the meat is cooled down before being canned. Canning is a method of preserving the luncheon meat for an extended period by sealing it in airtight containers. Often, preservatives are added during the canning process to further increase the shelf life of the luncheon meat. The entire process from deboning to canning requires precision and adherence to strict hygiene standards to ensure the quality and safety of the final product.

- Key Takeaway:

The production of luncheon meat goes through various meticulous steps to ensure its quality and safety. The first step involves grinding the meat, which usually includes a mix of pork, beef, or poultry, along with seasonings and additives. This process helps to achieve the desired texture and consistency for the luncheon meat. The ground meat is then carefully cooked to a specific temperature to kill any harmful bacteria and ensure the meat is safe for consumption. Cooking also helps to enhance the flavor of the meat and allows the seasonings to blend well with the meat.

After cooking, the next crucial step in the production of luncheon meat is the preservation process through canning. Canning involves sealing the cooked meat in airtight containers, usually cans, to prevent the growth of bacteria and spoilage. The canned luncheon meat is then heated to kill any remaining bacteria that could cause the product to spoil. This preservation method helps extend the shelf life of the luncheon meat and allows it to be stored for an extended period without the need for refrigeration. Canning also helps to maintain the flavor and texture of the meat over time, ensuring a consistent product for consumers.

In addition to grinding, cooking, and canning, quality control measures are implemented throughout the production process to ensure the luncheon meat meets specific standards. This includes regular testing for food safety, monitoring the cooking temperatures, and inspecting the canned meat for any defects. By following strict production protocols and quality control measures, manufacturers can produce high-quality luncheon meat that is safe, flavorful, and has a longer shelf life. The combination of these steps ensures that consumers can enjoy luncheon meat that is not only convenient but also delicious and safe to eat.

Types of Luncheon Meat

Exploring the diversity of luncheon meat varieties based on meat type, ingredients, and preservation techniques.

- Varieties and Nomenclature:

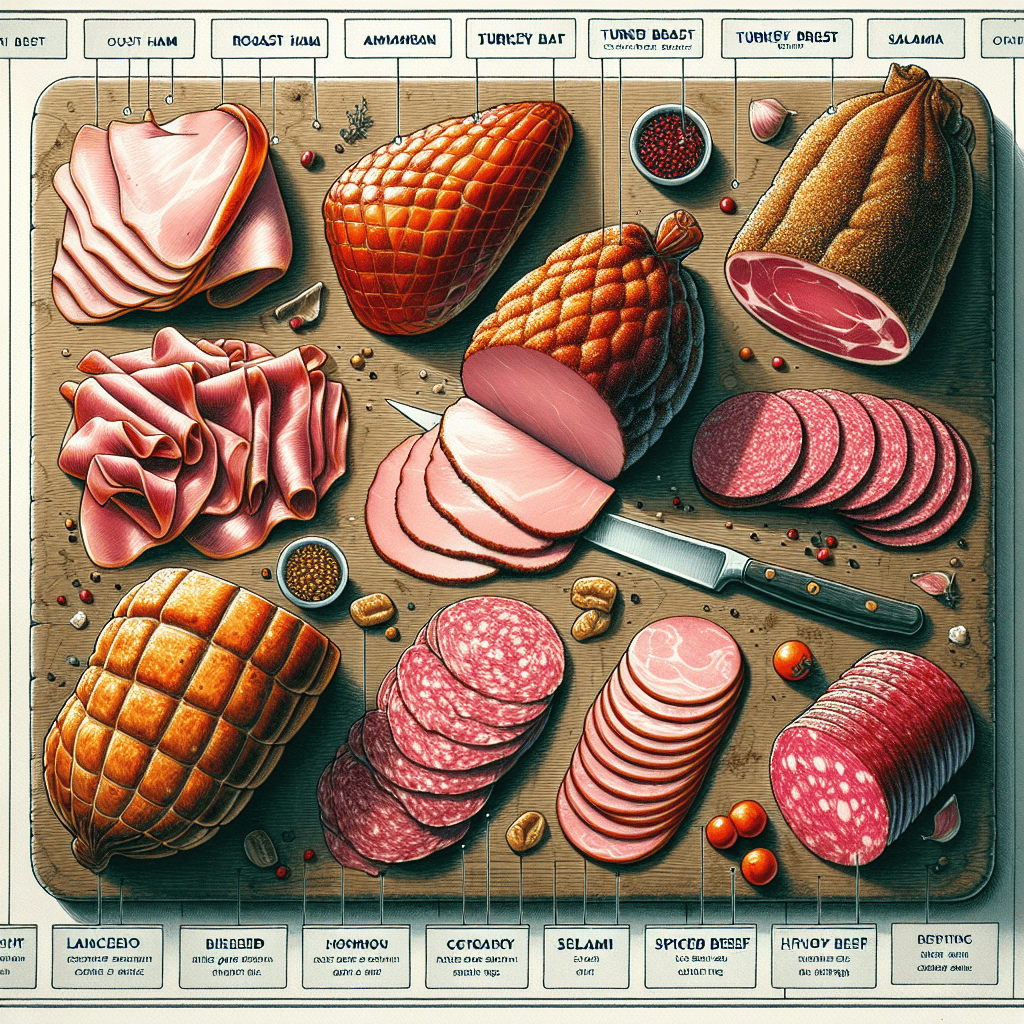

Luncheon meat, also known as lunch meat or cold cuts, comes in a wide array of variants depending on the type of meat used in its production. Some common types of luncheon meat include Bulabif, which is a type of luncheon meat popular in the Philippines made from ground pork or beef mixed with various spices and seasonings. Pastrami, on the other hand, is a popular luncheon meat originating from Romanian and Jewish cuisines, typically made from beef brisket that is cured with a mix of herbs and spices before being smoked and steamed. Salami, another well-known luncheon meat variety, is an Italian dry-cured sausage typically made from pork, though variations using beef or a mixture of meats are also common. Mortadella is another popular luncheon meat variant, particularly in Italy, made from finely ground pork that is delicately flavored with spices and cubes of fat.

In addition to the type of meat used, luncheon meat variants can also differ based on the manufacturing process employed. For example, Bulabif is often prepared by grinding the meat, mixing it with seasonings, and then shaping it into loaves or patties before cooking or smoking. Pastrami, in contrast, undergoes a more complex process involving curing, smoking, and steaming to develop its characteristic flavor and texture. Salami is fermented and air-dried, allowing it to develop its distinct tangy flavor profile. Mortadella, similarly, is finely ground and mixed with seasonings before being stuffed into casings and cooked, resulting in a smooth and flavorful luncheon meat with visible cubes of fat.

Furthermore, luncheon meat variants may contain added components like spices, herbs, garlic, and even pieces of nuts or fruits to enhance their flavor profile. Additionally, the preservation method employed can greatly influence the taste and texture of luncheon meats. Some luncheon meats are dry-cured or fermented, allowing them to develop deep, complex flavors over time. Others may be smoked or cooked to extend their shelf life and imbue them with a smoky or cooked taste. The wide range of luncheon meat variants available reflects the diverse culinary traditions and techniques used around the world to create these convenient and versatile meat products.

- Key Takeaway:

The variety of luncheon meats available in the market is greatly influenced by a combination of factors such as the type of meat used, the processing techniques applied, the ingredients incorporated, and the method of preservation. Different types of meat, such as chicken, turkey, beef, pork, or a blend of multiple meats, can be utilized to create luncheon meats. Each type of meat brings its unique flavor and texture characteristics to the final product, catering to a diverse range of consumer preferences. For instance, turkey luncheon meat may offer a leaner option, while pork luncheon meat might have a richer taste.

The processing methods employed in the production of luncheon meats also play a crucial role in determining the final product’s texture, taste, and appearance. Various techniques like grinding, seasoning, curing, and cooking are used in different combinations to achieve the desired outcome. The processing method adopted can result in luncheon meats with varying levels of fat content, saltiness, and tenderness. Additionally, some luncheon meats undergo smoking or curing processes to enhance their flavor profile and extend shelf life.

The choice of ingredients used in luncheon meats further contributes to the overall quality and flavor of the product. Ingredients such as spices, herbs, sweeteners, and additives like preservatives or flavor enhancers are often incorporated to enhance taste, aroma, and shelf stability. The selection of high-quality ingredients and the careful balance of flavors are critical in creating a delicious and well-liked luncheon meat. Moreover, the preservation method utilized, whether through refrigeration, vacuum sealing, or canning, significantly affects the product’s longevity and freshness, ensuring that consumers can enjoy the luncheon meat over an extended period of time.

Preservation of Luncheon Meat

Insight into the preservation techniques employed to extend the shelf life of luncheon meat.

- Preservation Methods:

Luncheon meat, a popular convenience food, is preserved using various techniques to ensure a longer shelf life and maintain its quality. One common method is salting, where salt is used to draw out moisture from the meat, creating an environment that is unfavorable for bacterial growth. The reduction in moisture content helps prevent the meat from spoiling and also contributes to its characteristic texture.

Another preservation method involves the inclusion of nitrates or nitrate salts in luncheon meat. Nitrates are commonly used as preservatives in processed meats due to their ability to inhibit the growth of harmful bacteria, such as Clostridium botulinum, which can cause botulism. Nitrate salts, such as sodium nitrate or potassium nitrate, are added to the meat during the processing stage to extend its shelf life and enhance its color and flavor.

Additionally, sugar is sometimes used in the preservation of luncheon meat. Sugar acts as a preservative by binding to water molecules, making them less available for microorganisms to use for growth. This helps to reduce the water activity in the meat, which in turn inhibits the growth of spoilage-causing bacteria. The inclusion of sugar can also provide a slightly sweet taste to the luncheon meat, balancing out the flavors and enhancing its overall palatability.

- Key Takeaway:

Preservation methods for luncheon meat like salting, nitrates, and sugar are crucial in extending its shelf life. Salting is a traditional method used to preserve meat by drawing out moisture, which inhibits bacterial growth. The salt creates a hostile environment for microorganisms, slowing down spoilage. Nitrates, commonly found in cured meats, serve as antimicrobial agents, preventing the growth of harmful bacteria like Clostridium botulinum that can cause foodborne illnesses. Additionally, nitrates enhance the meat’s color and flavor. Sugar, on the other hand, acts as a preservative by lowering the water activity in the luncheon meat, making it less susceptible to spoilage. It also contributes to the overall taste profile of the product.

Furthermore, the combination of these preservation methods not only extends the shelf life of luncheon meat but also plays a significant role in maintaining its quality and safety for consumption. By controlling moisture content through salting and sugar, the growth of bacteria and fungi is constrained, which helps in preventing food spoilage. Nitrates act as an additional safeguard, especially against dangerous bacteria that thrive in low-oxygen environments. The balance of these techniques is essential to the overall preservation process, ensuring that the luncheon meat remains safe and appetizing for a longer period.

It is important to note that while these preservation methods are effective in prolonging the shelf life of luncheon meat, consumers should still follow proper storage guidelines to maintain its quality. Storing the meat in airtight containers in the refrigerator or freezer can further inhibit bacterial growth and prevent contamination. Additionally, being mindful of expiration dates and proper handling practices, such as avoiding exposure to high temperatures or cross-contamination, is key to enjoying luncheon meat safely. Overall, understanding the science behind these preservation techniques empowers consumers to make informed choices about the food they consume, ensuring both its longevity and nutritional value.